法格塞达与印象技术为满足全球汽车市场需求联手推出铝热成形(HFQ®)大批量产线。

IMPRESSION

TECHNOLOGIES AND FAGOR ARRASATE ANNOUNCE A PARTNERSHIP TO PROVIDE HIGH VOLUME

ALUMINIUM HOT FORM QUENCH (HFQ®) PRODUCTION LINE SOLUTIONS TO THE GLOBAL

AUTOMOTIVE MARKET.

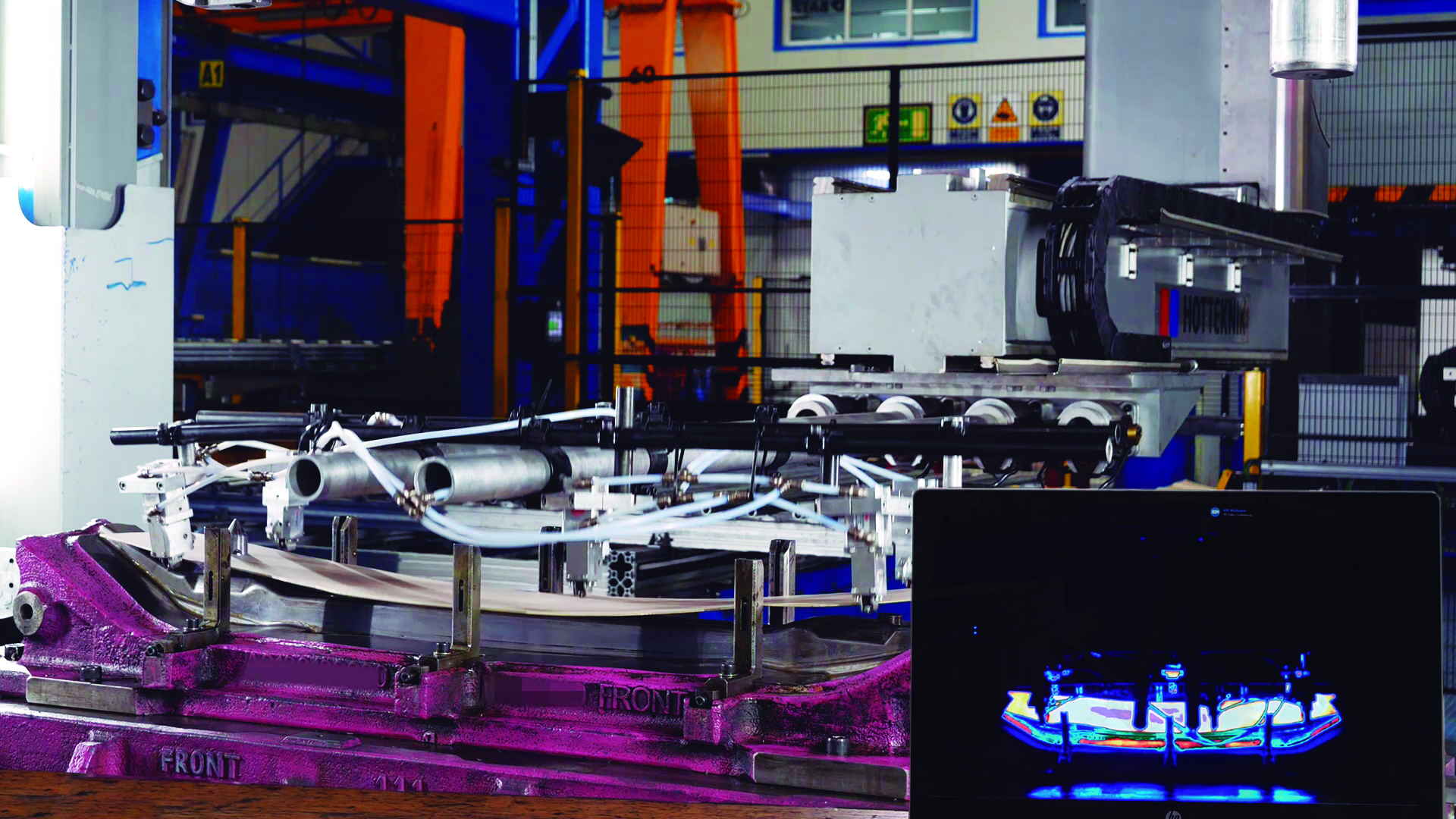

印象技术有限公司(“印象技术”)和法格塞达公司(“法格”)结合他们的专业知识,为热成形铝结构件提供全套技术和大批量生产解决方案。 印象技术,总部位于英国考文垂,开创且引领了铝热成形技术的发展,经过 20年的专业技术开发,涉及先进的合金表征、仿真模型、摩擦学和各种零部件与合金专门的工艺设计,实现了专利HFQ®技术工艺。 法格是全球钣金冲压解决方案的供应商,服务于包括汽车行业在内广泛的市场领域。

Impression Technologies Limited (‘ITL’) and Fagor Arrasate (‘Fagor’)

are combining their expertise to offer a complete high volume technology and

production solution for hot formed aluminium structures. ITL, based in Coventry

in the UK, is the originator and global leader in hot forming of aluminium

through its patented HFQ® Technology process, which is the culmination of 20

years of know-how development covering advanced alloy characterisation,

simulation models, tribology and process settings unique to each part and

alloy. Fagor is a global supplier of tailor-made solutions for sheet metal

stamping serving a wide range of market sectors, including automotive.

自2016年以来,HFQ技术已被阿斯顿·马丁(Aston Martin)和莲花(Lotus)等高端品牌使用,并被设计用于多个新的全球电动汽车平台,包括上车身结构、封闭件和电动系统外壳。 在欧洲、中国和北美的主要汽车产区,人们对汽车轻量化(尤其是电动汽车)热成形的应用兴趣正在迅速增长,这创造了对大批量铝热成形(HFQ)新生产线的需求。

HFQ Technology has been used by premium marques such as Aston Martin

and Lotus since 2016, and is being designed into several new global electric

vehicle platforms, including upper body structures, closures and electric

system enclosures. Interest in the application of HFQ for vehicle

light-weighting, particularly in electric vehicles, is growing rapidly,

creating demand for new high volume aluminium hot forming (HFQ) press lines in the

main automotive production regions of Europe, China and North America.

与主机厂与汽车零部件厂商建立非独家合作伙伴关系,提供材料、设计、工艺优化和生产线装备的专门组合,用于大批量生产超高强度6x和7x系列铝热成形件。 印象技术将负责所有与热成形零部件设计、模拟(包括必要的合金挑选和表征)和工艺规范相关的活动;法格将负责设计和交付具有竞争力且经HFQ认证的大批量生产解决方案。 汽车零部件厂商(或希望拥有自己的热成形加工能力的主机厂)可以自由地与每家公司单独合作或要求由法格单方实施经HFQ认证的交钥匙生产解决方案,并有机会获得热成形技术和得到印象技术的持续技术支持。 考虑到设计模拟和工艺参数之间的关键相互依赖以实现所需的机械和尺寸规范,印象技术与法格的技术集成将为汽车零部件厂商提供一个性能优化的解决方案,并减少工程介入投资。

The non-exclusive partnership offers tiers and OEMs a unique

combination of materials, design, process optimisation and manufacturing line

capability for the high volume production of ultra-high strength 6x and 7x

series aluminium HFQ components. ITL

will lead all activities relating to HFQ component design, simulation

(including alloy selection and characterisation, if necessary) and process

specification; and Fagor will take responsibility for the design and delivery

of a competitive and HFQ accredited high volume production solution. Automotive

tiers (or OEMs that wish to have their own HFQ capability) have the freedom to

work with each company independently or request a single turn-key and

accredited HFQ production solution led by Fagor, with access to HFQ Technology

and ongoing technical support from ITL. Given the critical

interdependency between design simulation and process parameters to achieve the

required mechanical and dimensional specifications, the technical integration

provided by ITL and Fagor will provide the tier an optimised capability

solution and reduced engineering burden.

印象技术公司首席执行官Jonathan Watkins表示:“我很高兴地宣布与法格塞达的新合作伙伴关系,法格塞达是领先的压机生产线制造商之一,其专长和能力与印象技术互补。 我们的问询数量创下了历史记录,我们的综合全面服务将促进HFQ技术的应用,并创建一个强大的全球供应网络。”

Jonathan Watkins, CEO of Impression Technologies commented “I am

delighted to announce this new partnership with Fagor Arrasate, one of the

leading press line manufacturers, whose skills and capabilities complement

those of ITL. We have had a record number of enquiries and our combined full

service offering will facilitate the adoption of the HFQ technology and the

creation of a robust global supply network.”

法格塞达首席执行官Unai Lopez补充说:“应对新技术挑战是法格 DNA的一部分。法格 – 印象技术的携手合作是面向所有那些愿意在冲压轻量化技术上迈出真正一步的公司。我们激动地宣布,这项新协议展现了该领域的颠覆性合作,是业界满足轻量化冲压要求的优选技术合作伙伴。”

Unai Lopez, CEO of Fagor Arrasate added “Coping with new

technological challenges is part of the DNA of FAGOR. FAGOR - ITL partnership

is addressed to all those companies that are willing to make a real step

forward in the stamping light-weighting technology. This new agreement, which

we announce with excitement, presents a game-changer collaboration in the

field, a preferent technological partner for the industry to hit the

requirements of the light-weight stamping.”

了解更多印象技术请咨询

For further information on Impression

Technologies:

Robert Stoff-Riegel

r.stoff-riegel@impression-technologies.com

www.impression-technologies.com

了解更多法格塞达请咨询

For further information on Fagor Arrasate:

Edorta Mendieta

市场部负责人

Head of Marketing Communications

e.mendieta@fagorarrasate.com

www.fagorarrasate.com

HFQ技术与供应网络请查询For information on HFQ Technology and

the supply network: https://hfqtechnology.com

编辑笔记:印象技术有限公司(ITL)和HFQ

Notes to editors on Impression

Technologies Limited (ITL) and HFQ Technology

印象技术是一家快速发展的轻量化解决方案公司,专注于应用HFQ热成形技术模拟和成形超高强度铝板结构件。 这种专用的技术通过授权许可的零部件厂商网络提供给主机厂,这些授权零部件厂商转而得到授权设备供应商、连接解决方案、模具、设计软件和合金供应合作伙伴的支持。 在某些情况下,主机厂可能需要安装自己的HFQ产线。

ITL is a rapidly growing

light-weighting solutions company specialising in ultra-high strength aluminium

sheet structures simulated and formed using its HFQ hot forming technology. This

unique technology offering is supplied to OEMs via an accredited network of

licensed tiers, who are in turn supported by providers of accredited equipment,

joining solutions, tooling, design software and alloy supply partners. OEMs, in

some cases may install their own HFQ lines.

HFQ技术为6000、7000和2000系列合金提供了成熟的解决方案,用于汽车,航空航天和消费市场,这些市场需要更轻,更强和更便宜的零部件,同时保持高尺寸和剩余延展性。 HFQ®技术压力机在高速下使加热铝板成形,在压力机模具中淬火,然后人工时效以实现最佳的强度。 应用于A柱和B柱、封闭件内部、电池外壳、座椅靠背/盘以及航空航天唇皮件。 印象技术在车身结构的同步工程和仿真方面具有强大的能力,能够以非常高的精度建模成形,并为任何适用的合金优化制造工艺。 高回收合金也被开发用于HFQ工艺。

HFQ Technology is a

proven solution for 6000, 7000 and 2000 series alloys for the automotive,

aerospace and consumer markets where lighter, stronger

and cheaper components are required, whilst maintaining high dimensional and

residual ductility performance. The HFQ® technology press forms hot aluminium

blanks at high speed, which are quenched in the press tool, followed by

artificial ageing to achieve full strength. Applications include A & B pillars, closure inners, battery

enclosures, seat back/pans and aerospace lip skins. ITL has strong capabilities in simultaneous

engineering and simulation of body structures, able to model formability with

very high precision and set optimised manufacturing configurations for any

applicable alloy. Highly recycled alloys are also being developed for the HFQ

process.

自2016年起,使用HFQ技术加工的结构件已在量产车辆上使用。 虽然还是一个相对年轻的公司,印象技术已经建成了HFQ大批量生产线,服务于汽车行业,包括德国费舍尔集团和中国的吉文集团。 其他合作伙伴包括美国的特乐斯环球和英国的SDE科技。 该制造零部件配套网络将在包括北美在内的所有地区扩张,以满足汽车主机厂对HFQ日益增长的需求,特别是在电动汽车制造商。

Structures

using HFQ have been in serial production vehicles since 2016. Whilst still a relatively young company, ITL

has established high volume HFQ manufacture lines serving automotive OEMs,

including fischer group in Germany and Jet Wagon in China. Other partners

include Telos Global in the USA and SDE Technology in the UK. The manufacturing

tier network is poised to expand in all regions, including North America to

meet the growing adoption of HFQ by OEMs, particularly for electric vehicles.

编辑笔记:法格塞达公司Notes to editors on Fagor Arrasate

法格塞达公司是设计和制造钢、铝、复合材料或热塑性材料复杂零件的材料成形定制化解决方案的世界翘楚。

Fagor Arrasate is a world leader in the

design and manufacture of tailor-made solutions for material forming to produce

complex parts in steel, aluminium, composites or thermoplastics.

法格塞达在全球范围内运营,用户包括大多数主流汽车主机厂和零部件供应商、钢铝卷及其板料的加工商、锻件或电炉轧钢生产商以及家用电器和金属家具制造商。

Fagor Arrasate operates globally and has

references at most major automotive OEMs and tier suppliers, processors of

coils and blanks in steel and aluminum, forged parts or electric rolled

steel producers, as well as manufacturers of home appliances and metallic

furniture.

公司在全球拥有6家工厂,产品分销至70多个的国家,大多数主流汽车主机厂、零部件供应商、钢铝卷及其板料的加工商、锻件或电炉轧制钢生产商以及家用电器和金属家具制造商安装有法格机器。

With six plants

worldwide, the company distributes its products to more than seventy different

countries with installations at most major automotive OEMs, Tier suppliers,

processors of coils and blanks in steel or aluminum, forged parts or electric

rolled steel producers, as well as manufacturers of home appliances and

metallic furniture.

结尾End

|